CE

|

BS EN 845

|

BS EN 846-2

|

BS 5977

|

Accelerated Water Tested- Saturated Freeze-Thaw

- Bond Strength - Pre & Post Weathered - Impact Strength - Pre & Post Weathered |

Austentic Stainless Steel- Grade 304 (1.4301) 316 (1.4404)

|

| Pro Steel Lintels Data Sheet | |

| File Size: | 2153 kb |

| File Type: | |

|

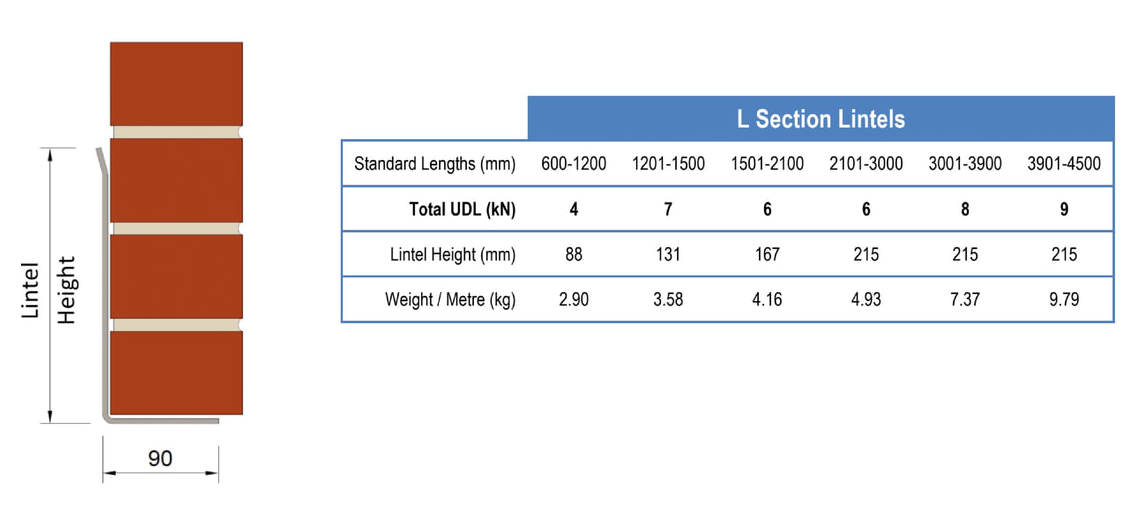

Technical Data

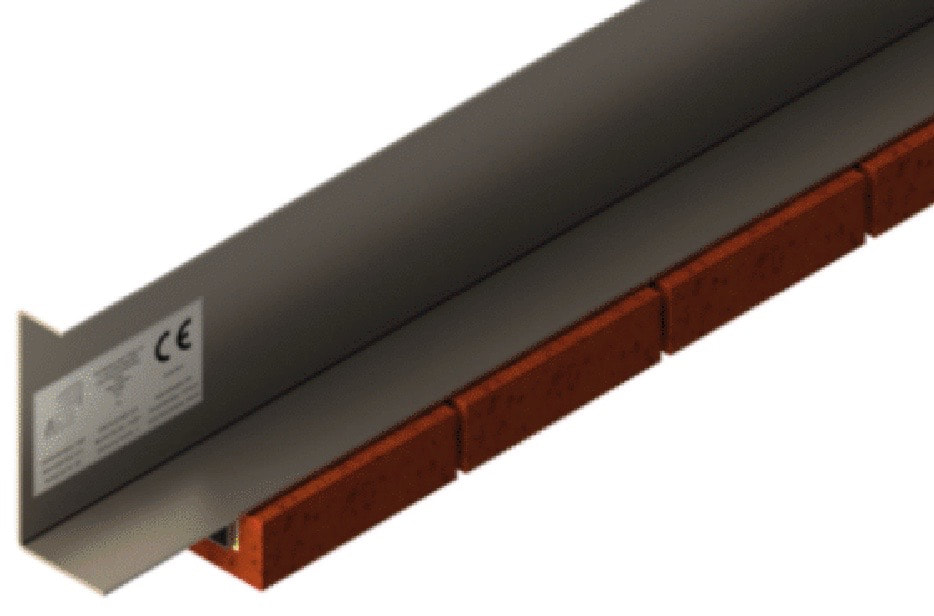

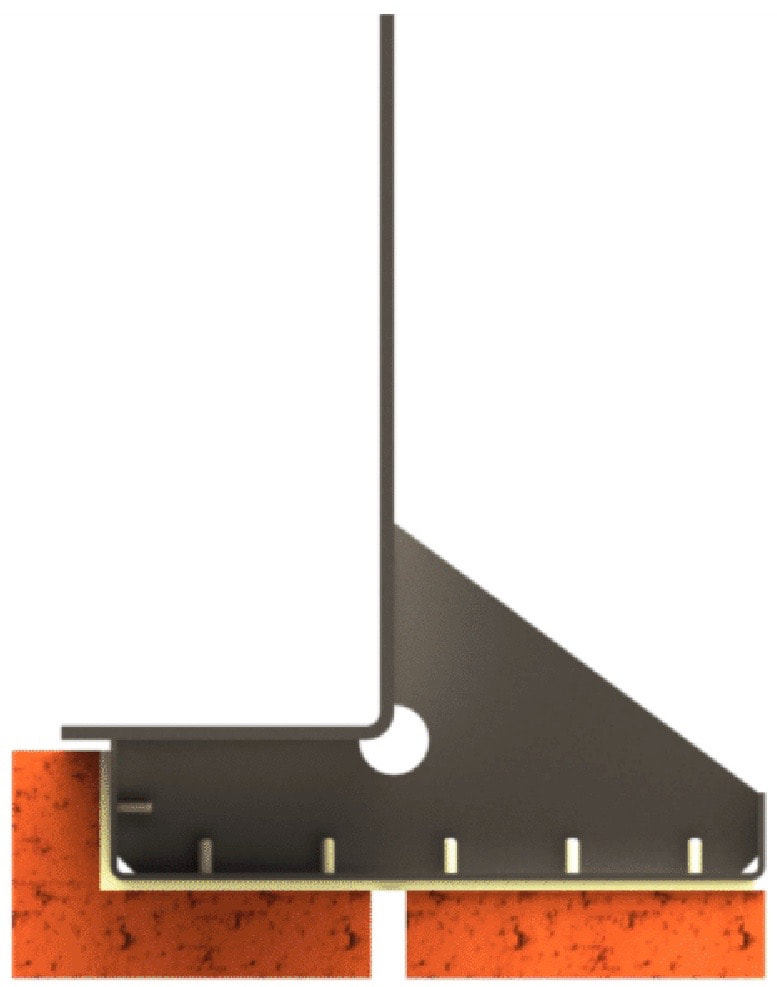

The Fab-Steel Stretcher Bond Lintel Range is designed to allow an opening to be created in a single leaf of masonry, typically the external leaf of a cavity with an integrated brick slip soffit feature. The brick slip soffit feature is bonded to the lintel carrier using a specially formulated resin adhesive in a stretcher/running bond to match seamlessly with the facing brickwork and reveals where relevant. |

|

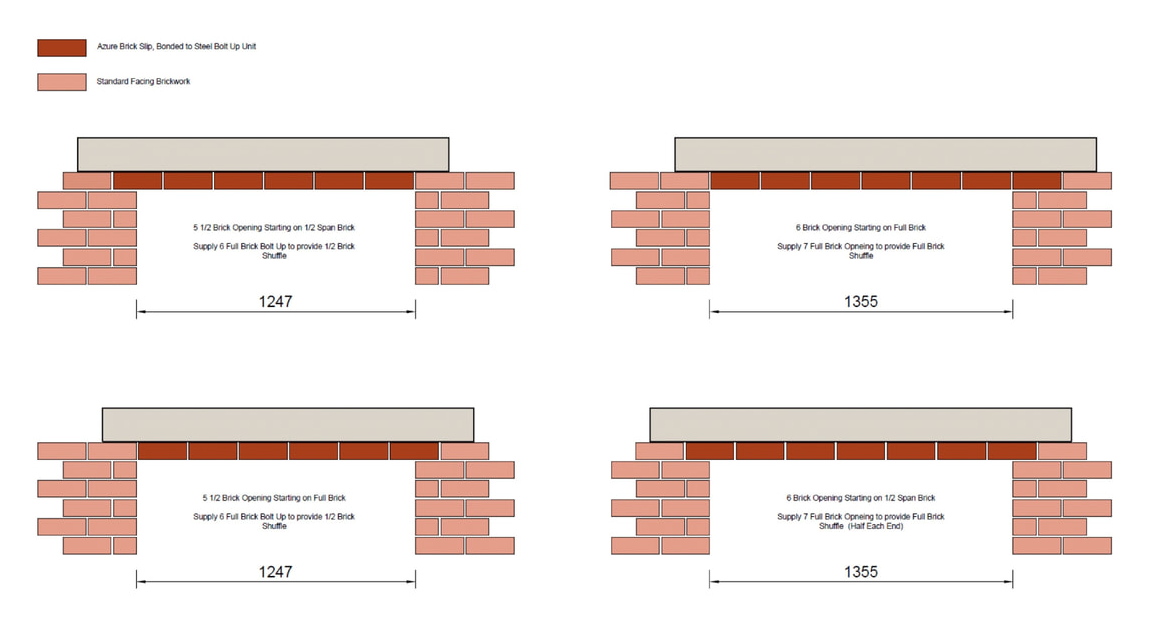

Shuffle Brick

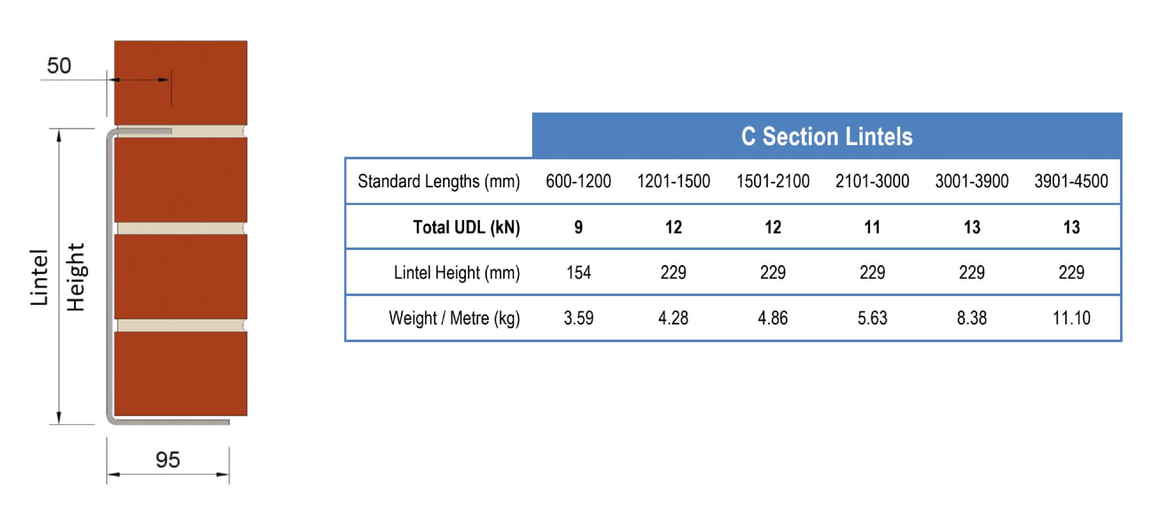

Fab-Steel brick faced lintels in Stretcher Bond are typically supplied with a ‘Shuffle Brick’ arrangement to allow the lintel to be coursed into the facing brickwork regardless of the bond pattern at the head of the opening (i.e starts on a half or full brick). Structural openings are most typically set at divisions of full or half brick dimensions, although we can adjust this to suit the bond pattern required. The illustration below demonstrates how the stretcher bond lintel should be set to accommodate for the various coursing conditions. Installation Lintels should always be propped during construction to achieve the safe working load capacities declared in the design tables below. A separate DPC is required above the lintel. Wall ties should be installed within 300mm of the lintel at a maximum of 450mm centres to ensure that the masonry carried by the lintel is restrained and any potential overturning and deflection is minimised. The standard lintel range is supplied in 150mm incremental lengths. Lintels of alternative lengths and load capacities outside of the details provided in the following load tables can be designed and supplied to meet with project specific requirements. Lintels should be selected to ensure that a minimum of 150mm bearing either side of the opening is always achieved. |

|

Lintels Testing info.

Both the lintels and the brick slips have been independently tested by Notified and Technical Approval Bodies to evaluate and validate the load capacity, physical performance and long term durability of all components. The lintels have been designed in line with the requirements of BS EN 845-2 & BS 5977-1 and tested in line with BS EN 846-9.

The brick slips are tested using the guidance of ETAG 034 to evaluate the accelerated Freeze/Thaw weather resistance both saturated and dried of the slips bonded to backing structures of various materials including stainless steel and powder coated galvanised steel. The tests include the evaluation of bond strength and durability of the brick slips bonded to stainless steel where a service life of 60 years can be achieved. The bond strength and impact resistance of the brick slips were tested before and after the accelerated cyclic weather tests to validate the integrity and durability of the system. The tests included: |

Technical Info.

*Click on the photos to enlarge drawings, for further information sign up to our architects lounge*

*Click on the photos to enlarge drawings, for further information sign up to our architects lounge*

Alternatively lintels can be designed to suit specific loading requirements outside of the standard range detailed in the tables above.

Ronald MacDonald House, Lambeth

Using long thin Handmade bricks from Charnwood Brick and beautifully crafted Natural Stone, only the highest quality detailing would be accepted on this prestigious building designed by AEW Architects.

Spring Mews, London

Long lengths of deep soffit lintels were manufactured as single piece structural lintels with bricks fabricated to the front and soffit. Another great site using a full range of lintels and bolt ups as well as drive through brick soffited areas.

Litchfield Pegasus Life

At our first meeting with the project Architects Proctor and Mathews they said this would be a real challenge to our capabilities as they had some highly unusual requirements for vertical corbel details to be incorporated within our lintel designs.