|

Pro-Clad™ can be used as a total or partial clad solution.

On areas where brick slips need to be built adjacent to traditional brickwork, consistency of colour and finish can be maintained by ensuring bricks are collected from site, cut down in thickness before being fabricated onto the lightweight backing boards using a Approved Resin manufactured to BBA Certified processes. |

|

Pro-Clad™ backing boards have been developed to have a low environmental impact and are Non-Combustible, suitable for internal or external use. The backing board incorporates a mesh layer to improve its strength and its ability to withstand impact without increasing the overall panel thickness.

It is resistant to water, rodents and mould in addition to its thermal and sound insulation properties. It is easy to work with and can be cut on site using a hand-held angle grinder fitted with a diamond tipped blade with appropriate PPE. It is chemically stable and Non Hazardous. |

The Pro-Clad Range

|

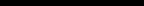

PRO-CLAD 1 / Our rectangular brick faced cladding system where the slips between the adjoining panels are fabricated on site once the panels have been installed, more suited to vertical wall areas were repetition in the panel size is required, whilst the panels are still 95% off site fabricated. The pro-clad 1 is our most competitive brick faced cladding panel system.

Certification: BBA Approved Cert No. 5475 |

|

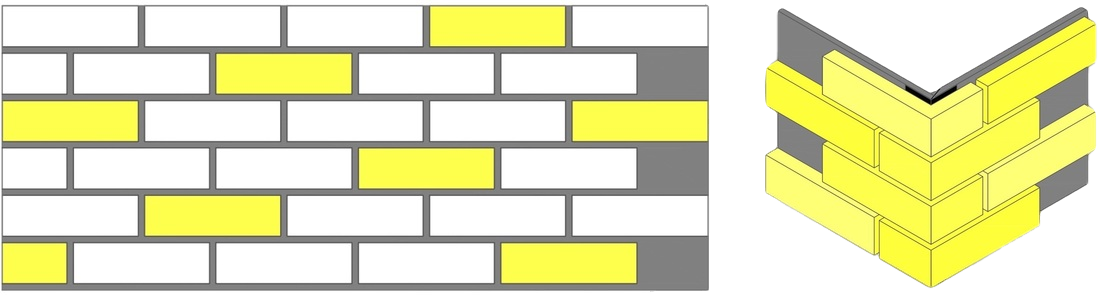

PRO-CLAD 2 / Our interlocking cladding panel system where no on site fabrication of slips is required, suitable for vertical and soffit application the PC2 system is usually designed site specific to fit the areas required.

Certification: BBA Approved Cert No. 5475 |

|

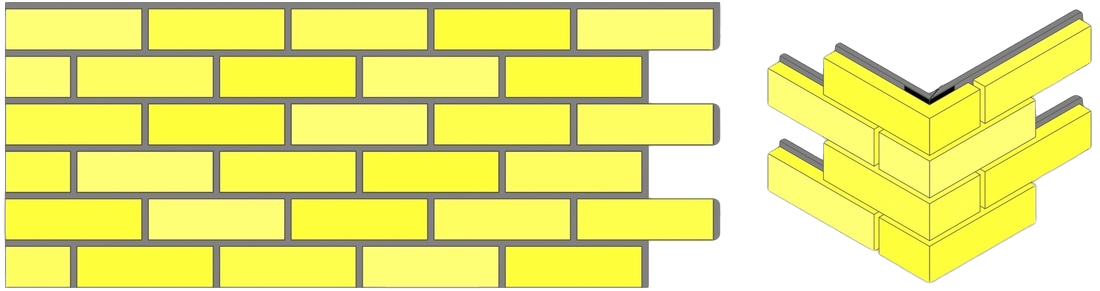

PRO-CLAD 3 / Developed from our PC2 system but with the addition of a mechanical fix to each slip alongside the resin bonded adhesion of the brick slips to our carry panel.

Certification: Lucideon EAD090062/00-0404:2018 |

Pro-Clad in depth...

|

Pro-Clad as well as being BBA certified, it has also been fully tested independently by Lucideon to etag 034 standards. All products are also manufactured to ISO 9001:2015 managed quality control standards.

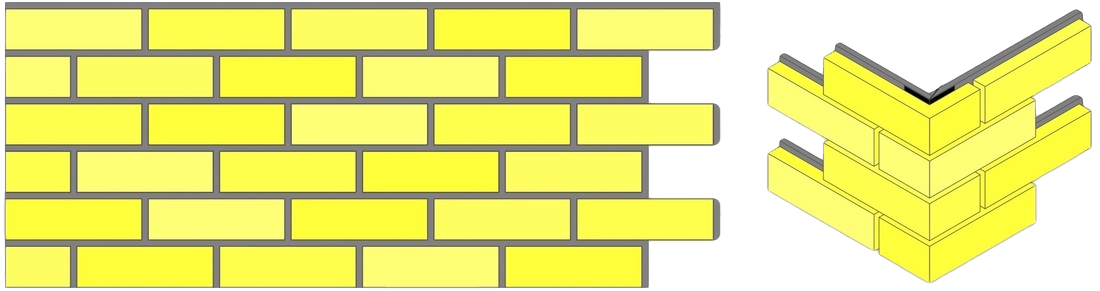

The brick finish can vary to suit designer's requirements. Pro-Clad can also be produced in any brick bond pattern and orientation. Bricks collected from site are cut down in thickness in our in house production facility before being fabricated to the approved Pro-Clad panel set out details. |

|

Whilst the Pro-Clad real brick cladding system can be manufactured using any standard facing brick, we also have an extensive range of purpose made brick slips that are manufactured as a brick slip/tile for the brick cladding market.

All the brick slips are set into a steel template or jigs that ensure exact positioning of the slips to ensure the interlocking of the panels. Giving the appearance of continuous brickwork with no visible seem between panels. The fixings are hidden within the joints and covered with the pointing material. The panels are supplied with stainless steel fixings for a variety of different substrates that the panels can be fixed to including timber batons, aluminium cladding rails, block work/concrete and plywood constant. The fixings come with full technical support for pull off and pull through testing for each application. The Pro-Clad™ panels can produce large areas of cladding off site as a cost effective solution to alternative methods of forming brickwork either traditionally or using other kit form systems. The advantages of off site production in UK without weather dependency and a rapid, quality controlled product make it a popular choice. |