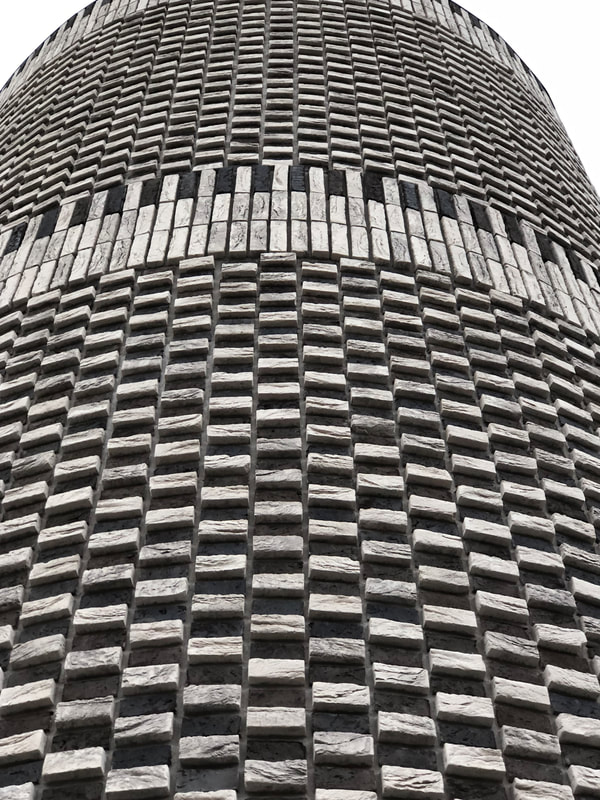

Hoe Street, London

A unique project manufactured in Pro-Clad 2. Hoe Street, London was produced in two different 50mm course heights. The brick type was specified to achieve chequer board appearance to the brick cladding finish which can be seen from the photos below.

Site had major problems in trying to source cladding panels that produced a curved brick appearance, Fab-Cladding were able to overcome this issue and with the added benefit of keeping a real brick finish for authentication.

Site had major problems in trying to source cladding panels that produced a curved brick appearance, Fab-Cladding were able to overcome this issue and with the added benefit of keeping a real brick finish for authentication.